- #USE CLICK PLC AS MODBUS SERVER SOFTWARE DOWNLOAD#

- #USE CLICK PLC AS MODBUS SERVER DRIVER#

- #USE CLICK PLC AS MODBUS SERVER SOFTWARE#

- #USE CLICK PLC AS MODBUS SERVER PC#

- #USE CLICK PLC AS MODBUS SERVER LICENSE#

#USE CLICK PLC AS MODBUS SERVER PC#

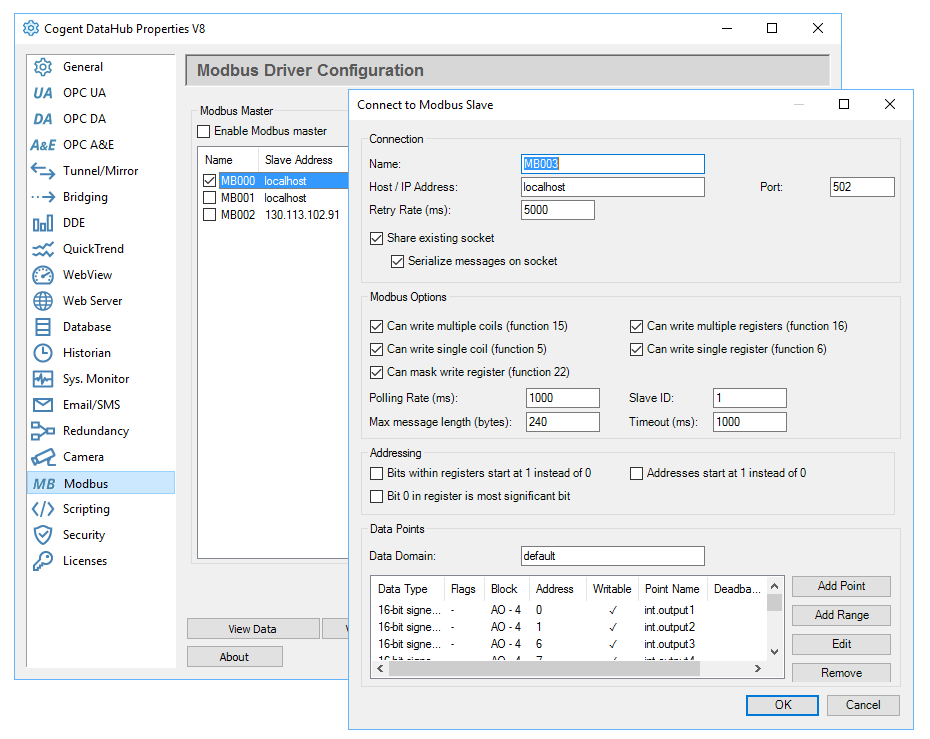

If you know that your PLC with Modbus support is up and running but you cannot connect make sure that neither your PC nor your company network is protected by a firewall that blocks communication with the required TCP port.Sets the numerical value of all holding registers in the selected address range to the desired value.įIG 4: Available commands for writing TROUBLESHOOTING If needed input values can be divided by entering an value in ‘Divide’. Only integers can be written, positive or negative. Sets the numerical value of a single holding register at the selected start address to the desired value. Input of values > 1 set the bit to 1, values 1 sets all bits to 1, values < 0 sets all bits to 0. Sets the status of a single bit at the selected start address to 0 or 1. If needed you can verify the result by executing function ‘Read Bits’. The result of the writing operation shows up in the right area (11).Input the desired value into field ‘Write Value’ (9), here 1.Commands that write single values use ‘Start Address’ as target. Select one of the available commands for writing, here ‘Write Bit’ (7) and select a target address, here 1 (8).Make sure that you can read values from the desired address or address range.To write values to a PLC proceed as follows: Input Bits and Input Registers are read only. ModbusGui can also be used to set values of writable bits and registers at a remote device. Note: If needed, output values of register and input registers can be divided by entering a divisor in field ‘Divide’. Reads the numerical values of multiple physical analog inputs from the selected address range. Values of holding registers read by this function have to be maintained by the PLC program, otherwise the output is 0. Reads the numerical values of multiple holding registers from the selected address range. Reads the status (0/1) of multiple physical digital inputs of the remote device from the selected address range. Reading of bits only makes sense if the value at a specific address is maintained by the PLC program, otherwise you just get 0. Reads the status (0/1) of multiple bits (aka Coils) from the selected address range. Clicking on (5) shows the result of the operation in the output area (6), here Bit 8257 is set to 1.Initially ‘Read Bits’ is selected which reads multiple Bit values (0 or 1) from Start to End-Address (4), here from 8250 to 8261. Select one of the available commands (3).Enter the TCP Port used for communication (2), default 502.Slave ID is only required for specific devices, Timeout only has to be increased for very slow network connections, leave at 500 (= 0.5 sec.). Input IP Address or DNS Hostname of your PLC (1).You can use our tool Device Port Scanner to check if the device is reachable via this port. In case you use a firewall at your PC or your company network please make sure that there is an exception for the TCP Port your PLC uses (default: 502). Note: If you like to run this program from a different folder on your PC you can simply copy your CNCnetPDM.ini file to this directory.ĭownload and extract all contents of modbus_test.zip to a folder on your PC.Please see licensing for details or contact us if you have any questions. Otherwise you can only Read Bits from a remote device.

#USE CLICK PLC AS MODBUS SERVER LICENSE#

If you have installed CNCnetPDM on your PC with a license other than a ‘free license’ and run this program from the folder where CNCnetPDM is installed you get unlimited functionality. For a Modbus TCP slave-client that runs on TCP port 502 with Slave Id 9 run it from a command prompt at a local or remote PC with the following arguments:

#USE CLICK PLC AS MODBUS SERVER SOFTWARE#

Next, setup the device to allow Modbus access and add at least one Ethernet Modbus Server Connection with a TCP port for remote communication (default: 502). To test reading and writing operations first make sure that the controller is connected to the network and setup with an IP Address reachable from your PC.

#USE CLICK PLC AS MODBUS SERVER SOFTWARE DOWNLOAD#

PLC SETUP | SOFTWARE DOWNLOAD | LICENSING | SOFTWARE SETUP | READ DATA | WRITE DATA | TROUBLESHOOTING PLC SETUP The application can be executed on a PC with MS Windows OS (>= XP SP3) connected to PLCs or any electronic device that supports Modbus TCP protocol (Server mode) via Ethernet.

#USE CLICK PLC AS MODBUS SERVER DRIVER#

It assists to quickly setup customized PLC device driver INI files for CNCnetPDM. For Programmable Logic Controllers (PLC) this diagnostic tool allows you to test reading and writing operations.

0 kommentar(er)

0 kommentar(er)